Organizations look for ways to improve their processes and often expect that big steps are needed to achieve results.

However, the simplest solutions can be the most efficient. And when it comes to lean manufacturing, standardized work instructions are a way of driving operational excellence and innovation.

Benefits of standardized work instructions

While standardization defines the best way of performing a task, its effects come a long way in lowering costs and improving product quality.

By applying clear guidelines, you always know how processes will unwind and minimize human errors. It also ensures consistency in results – no matter how skilled a worker is – so it is easy to meet quality standards.

Eliminating variability and human error

It is human to make mistakes. In fact, more than 80% of errors on manufacturing sites are human errors. Standardized instructions eliminate their occurrence, as workers follow instructions step-by-step and carry out tasks with absolute precision. SOPs should produce consistent results without unpleasant surprises.

Meeting quality standards

Standardized work instructions collect the best possible practices that are developed to adhere to various standards, certifications, and requirements. When every worker performs a task in the exact same way every time, it ensures that quality expectations are being met.

Retaining knowledge

Aging workforce, staff fluctuation, and skill gaps are challenges countless organizations face. Creating standardized instructions includes recording daily procedures and documenting tribal knowledge to draft the best work guides.

Knowledge stays within the organization long after workers decide to retire or move on. Furthermore, by documenting performed tasks, it helps organizations to identify bottlenecks and come up with solutions that can improve operations in the long run.

How does it work in practice?

Standardizing your processes is a significant step on a way to leaner operations. However, there are several factors you should take into consideration. How should the instructions look like? What format workers prefer? And what to do when a better practice comes along?

When it comes to standardized work instructions, they should be:

- Accessible and stored conveniently, so they won’t slow workers down when solving problems

- Clear, easy to follow, and complete

- Easy to update to keep them accurate and relevant

Digitalization of instructions

In case of an issue (e.g. an unexpected machine shutdown), work instructions should be easy to find and access. Busy frontline workers shouldn’t be required to walk up to the production office and search through paper binders. You can streamline the information flow by giving them a digital version.

Set up standardized digital instructions nearby workstations, where workers can access documents by using search engines or QR codes. Less time spent on looking for information means shorter downtimes.

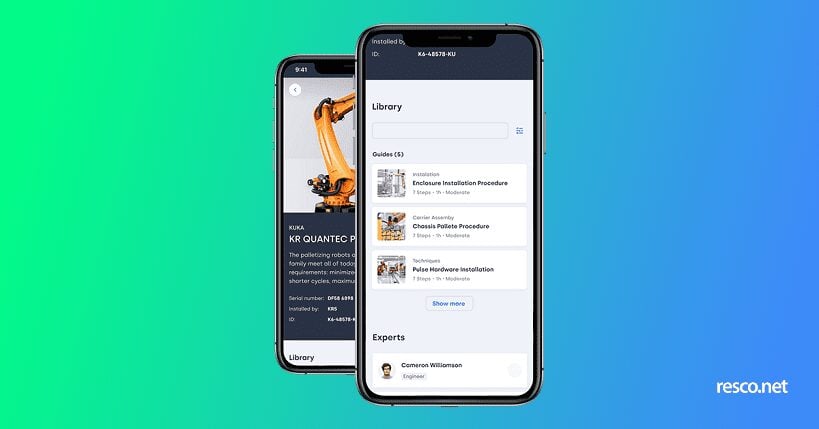

Digitalized standardized work instructions can be put into great use also in the field. Technicians can have all the necessary SOPs and manuals in a single mobile device. With step-by-step instructions guiding them through their work, they can carry out tasks autonomously and efficiently.

Easy to follow guides

Instructions that clearly describe each step without unnecessarily difficult and technical language help workforces to grasp what´s expected of them. No errors or accidents on the shop floor – only increased productivity and quality of product.

Furthermore, work instructions enhanced by images, animations, videos, or other multimedia files improve retention of information. Showing workers what to do and how exactly to do it, they are a great tool for training and overcoming language barriers.

With visual instructions, reskilling and onboardings can be completed faster – while providing organizations new opportunities to identify and close skill gaps in the workplace.

Updating and collaboration

If something ages quickly, it is work instructions – which is a good and a bad thing at the same time. It means that processes keep evolving and improving, but also that SOPs can fast become irrelevant. More than 70% of manufacturers use instructions that are outdated.

That’s is why it’s important to keep your knowledge stored on a platform where it can be efficiently edited and updated, e.g. a dedicated knowledge software.

Many organizations also decided to decentralize the creation of instructions by enabling their workers to give feedback on current practices and document their tasks. This way, they can participate on improving and building an organization´s knowledge base and retention of tribal knowledge.

Use work instructions and boost your operations with Resco Steps+

Resco Steps+ is a knowledge management application that will help you keep up with the competition.

All tribal knowledge, guides, and manuals are packed in a single app. Empower workers by sharing expertise in real time and improving your operations efficiency with knowledge at your teams’ fingertips.